Categories more

- Adventures (17)

- Arts / Collectables (15)

- Automotive (37)

- Aviation (11)

- Bath, Body, & Health (77)

- Children (6)

- Cigars / Spirits (32)

- Cuisine (16)

- Design/Architecture (22)

- Electronics (13)

- Entertainment (4)

- Event Planning (5)

- Fashion (46)

- Finance (9)

- Gifts / Misc (6)

- Home Decor (45)

- Jewelry (41)

- Pets (3)

- Philanthropy (1)

- Real Estate (16)

- Services (23)

- Sports / Golf (14)

- Vacation / Travel (60)

- Watches / Pens (15)

- Wines / Vines (24)

- Yachting / Boating (17)

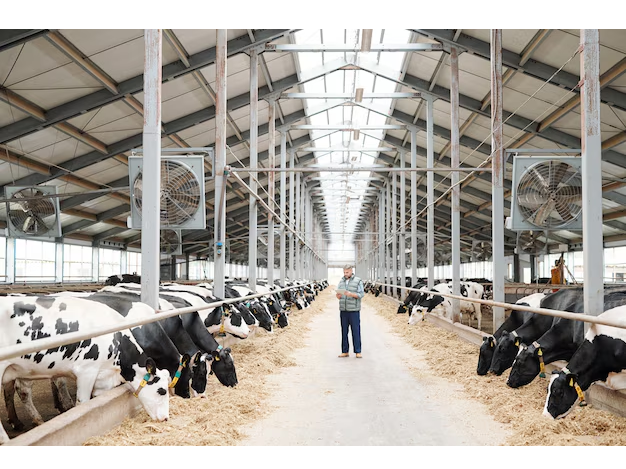

Choosing the Right Exhaust Fan for Your Livestock Barn

Published

12/28/2024Proper ventilation is vital for maintaining air quality and comfort in a livestock barn.

A carefully selected exhaust fan helps control temperature, reduce humidity, and improve airflow, promoting healthier conditions for your animals.

This guide covers key factors like cubic feet per minute (CFM), static pressure, and noise levels to help you make an informed choice.

With the right fan, you can create an efficient and comfortable environment that supports both animal well-being and operational needs.

By focusing on essential criteria, this guide ensures your barn is equipped with the optimal tools to support both animal welfare and operational efficiency.

Understanding Ventilation Requirements in Livestock Barns

Proper ventilation is critical for ensuring a healthy environment in livestock barns. Without it, heat, humidity, and ammonia levels can rise, leading to discomfort for animals and potential health problems.

Effective ventilation regulates these factors by exchanging stale air with fresh air, maintaining optimal conditions for your livestock.

Factors influencing ventilation needs include the barn size, the number of animals housed, and local climate conditions. Seasonal variations also play a role, with hot summers requiring higher airflow rates to mitigate heat stress.

Poor ventilation can lead to significant issues such as reduced productivity, respiratory problems in animals, and the accumulation of harmful gases. Addressing these challenges with a well-planned ventilation system can improve both animal welfare and operational efficiency.

Key Parameters to Consider

When selecting a barn exhaust fan for livestock, understanding the critical parameters ensures the ventilation system meets both performance and efficiency requirements. Here are the main factors to evaluate:

1. Cubic Feet per Minute (CFM)

CFM measures the amount of air a fan can move in a minute. It’s essential to determine the airflow needs of your barn to maintain proper ventilation.

Calculating CFM:

- Measure the barn's dimensions: length, width, and height.

- Multiply these dimensions to get the barn’s volume.

- Divide the volume by the desired air exchange rate based on the barn's purpose.

For example, barns typically require 12 to 18 air changes per hour for optimal ventilation. The chart below provides recommended air changes for different spaces:

|

Area |

Min Changes per Minute |

Max Changes per Minute |

|

Barn |

12 |

18 |

|

Kitchen |

1 |

5 |

|

Residence |

2 |

8 |

|

Office |

2 |

8 |

|

Restaurant |

5 |

10 |

The bar chart above visually highlights these air change requirements, helping you assess the appropriate ventilation rates.

2. Static Pressure (SP)

Static pressure refers to the resistance to airflow within the ventilation system. Factors such as duct length, number of bends, and accessories like filters contribute to this resistance.

Key Guidelines for SP:

- Non-Ducted Systems: SP ranges from 0.05 to 0.20 inches of water gauge.

- Ducted Systems: SP increases by 0.2 to 0.40 inches per 100 feet of duct length, depending on air velocity.

- Accessories like elbows and dampers typically add 0.08 inches per fitting.

Proper fan selection ensures it can overcome this resistance to maintain consistent airflow. Importantly, always account for makeup air—each cubic foot of air exhausted must be replaced to avoid pressure imbalances.

3. Noise Levels (Sones)

Noise is an important consideration, particularly for livestock, as excessive sound levels can induce stress. Fan noise is measured in sones, with lower values indicating quieter operation.

Suggested Sone Levels for Various Areas:

|

Sones |

Room Type |

|

1.3 to 4 |

Rural homes, barns |

|

3 to 9 |

Courtrooms, apartments, urban barns |

|

7 to 21 |

Supermarkets, farm kitchens |

For livestock barns, aim for fans with some ratings that align with the quieter range of these values to ensure animal comfort.

4. Energy Efficiency

Energy consumption is a critical factor in reducing operational costs. Consider:

- Fans with variable speed motors to adjust airflow based on real-time needs.

- Energy-efficient motors to lower power usage during peak operations.

Investing in efficient fans not only saves costs but also reduces the barn’s environmental impact.

Choosing the Right Fan Type

Direct Drive vs. Belt Drive Fans

Direct drive fans are simple and low-maintenance, ideal for low airflow needs and lower static pressures. In contrast, belt drive fans are better suited for high-volume airflow and environments with greater resistance.

Axial vs. Centrifugal Fans

Axial fans are suitable for moving large volumes of air at low static pressure and are commonly used for general ventilation. Centrifugal fans, on the other hand, are efficient at handling higher static pressures and are quieter, making them a better choice for enclosed spaces with ductwork.

Location-Specific Fans

Select fans based on their placement:

- Roof-mounted fans for large-scale ventilation.

- Wall-mounted fans for direct air movement.

- Duct-mounted fans for targeted airflow in specific areas.

Advanced Features to Look For

Modern fans come with advanced features designed to optimize performance. Variable speed motors allow for precise control over airflow, reducing energy costs during periods of low demand.

Fans with corrosion-resistant materials, such as stainless steel or special coatings, are essential for barn environments with high humidity and ammonia levels.

Additionally, smart controls offer real-time monitoring of fan performance, enabling predictive maintenance and reducing downtime.

These systems can alert you to potential issues before they become costly problems, ensuring consistent operation.

Maintenance and Longevity

Regular maintenance ensures fans perform efficiently and have a long service life. Look for fans with simple designs that allow for easy cleaning and servicing.

Choose models from manufacturers known for their reliability and availability of replacement parts.

Routine checks for dust buildup, belt wear, and motor efficiency will extend the lifespan of your equipment.

Calculating Total Cost of Ownership

When selecting a fan, consider the total cost of ownership rather than focusing solely on the initial purchase price. Factor in:

- Energy consumption over time.

- Maintenance costs.

- Durability and replacement needs. A higher upfront investment in energy-efficient or durable models often translates to lower overall expenses and better performance in the long run.

Common Mistakes to Avoid

- Undersizing or Oversizing Fans: Choosing a fan that’s too small or too large for the barn can lead to inefficiencies and increased costs.

- Ignoring Static Pressure: Overlooking the impact of duct resistance or makeup air can reduce system performance.

- Neglecting Noise Levels: High noise levels can stress animals, impacting their health and productivity.

- Overlooking Energy Efficiency: Failing to prioritize energy-efficient models can result in unnecessary operating expenses.

Conclusion

Selecting the right exhaust barn fan for your livestock barn is crucial for maintaining animal health, comfort, and operational efficiency.

By carefully evaluating airflow needs, static pressure, noise levels, and advanced features, you can ensure your barn has an effective barn ventilation system.

Investing in high-quality, durable fans designed for barn environments not only enhances productivity but also reduces long-term costs.