Categories more

- Adventures (17)

- Arts / Collectables (15)

- Automotive (37)

- Aviation (11)

- Bath, Body, & Health (77)

- Children (6)

- Cigars / Spirits (32)

- Cuisine (16)

- Design/Architecture (22)

- Electronics (13)

- Entertainment (4)

- Event Planning (5)

- Fashion (46)

- Finance (9)

- Gifts / Misc (6)

- Home Decor (45)

- Jewelry (41)

- Pets (3)

- Philanthropy (1)

- Real Estate (16)

- Services (23)

- Sports / Golf (14)

- Vacation / Travel (60)

- Watches / Pens (15)

- Wines / Vines (24)

- Yachting / Boating (17)

Published

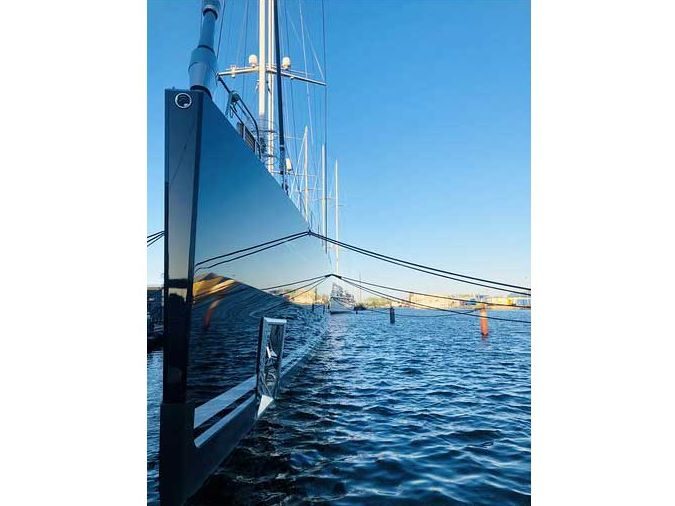

06/26/2020 by Royal HuismanA successful series of sail trials marked the concluding stage and upcoming delivery of the truly breathtaking three-masted Royal Huisman schooner SEA EAGLE II: the world’s largest aluminium sailing yacht.

Earlier this year, SEA EAGLE II, designed by Dykstra Naval Architects and Mark Whiteley, was transferred from the shipyard’s headquarters in Vollenhove and launched in Amsterdam. Her three carbon Rondal masts and booms were installed and tuned at Royal Huisman’s Amsterdam facility. The 81m / 266ft contemporary schooner was perfectly on schedule for her delivery date, but Covid-19 restrictions in the Netherlands prevented the finishing touch - trials on the North Sea - from being completed.

Nearly all board systems, such as gensets, air conditioning, waste water treatment and electronics, were thoroughly tested in the year prior to launch to avoid any surprises during the commissioning stage. Strict Covid-19 regulations and detailed protocols introduced in Spring eventually allowed the team to safely “pick up where they left off” in these extraordinary times. The sail handling and remaining propulsion systems were successfully tested and signed off during recent trials, which even during testing gave very promising insights into this yacht’s capabilities!

Spectacular speeds over 21 knots can be achieved in the ultimate sustainable way by powering up SEA EAGLE II’s Rondal rig, which can carry over 3500 square meters of sail area evenly distributed over her carbon Panamax masts. The full sail area is controlled by 34 winches from sailing system integrator Rondal. The largest winches - for the yankee, staysail sheets and mizzen sheet runners - are capable of a tremendous 18 tons (18000kg!) pulling load.

Royal Huisman’s largest yacht ever was commissioned by the Owner of the 43m / 142ft sloop SEA EAGLE (Royal Huisman, 2015) who in doing so, reaffirmed his confidence in the ability of the shipyard to build his ultimate dream-yacht. SEA EAGLE II features a plumb bow, ensuring she is not only powerful but recognizable all over the world. The Royal Huisman team made this grand aspiration into a striking reality, keeping its promise of “If you can dream it, we can build it”. Delivery of this impressive and already iconic superyacht SEA EAGLE II is scheduled for July 2020.

Integrated Sailing System by Rondal

SEA EAGLE II’s three carbon composite masts comprise main, mizzen, fore and furling booms, which are styled and shaped to match the design of the yacht. The total area of the sails (by Doyle Sails) is distributed among the three masts providing the freedom of various sail configurations for various weather conditions.

The Panamax*) masts are designed for an optimal balance between strength, stiffness and weight, and are manufactured in carbon composite. An impressive feature is that each Rondal mast is built as one piece. This means that for 80% of the masts’ thickness, full length, uninterrupted carbon fibre laminates were applied, giving the mast unique properties with a perfectly even strength distribution – resulting in a beautiful even bend, so no ‘hard spots’.

*) Panamax refers to the maximum dimensions of a ship permitted to pass the locks in the Panama Canal. The sailing world has coined the word Panamax to express the maximum air draft of an upright yacht’s mast in order that it may clear the Bridge of the America’s on the Pacific side of the Canal. At median low water this is around 62m / 205ft.

A vital role was played by Rondal realizing the Integrated Sailing System for SEA EAGLE II. This unique approach delivers optimization of sailing components and systems through an expert process of design and engineering. This holistic approach leverages decades of superyacht experience, composite expertise and strong partnerships to realise the project with unrivalled ease of sail handling, quality and performance.

Rondal’s Integrated Sailing System consists of the three carbon Panamax masts with furling booms, hydraulic boomvangs, headsail furling systems, deck winches and equipment, captive winches and continuous solid carbon standing rigging by Carbo-Link, all equipped with load sensing capabilities.