Categories more

- Adventures (16)

- Arts / Collectables (14)

- Automotive (36)

- Aviation (10)

- Bath, Body, & Health (73)

- Children (6)

- Cigars / Spirits (30)

- Cuisine (16)

- Design/Architecture (17)

- Electronics (12)

- Entertainment (4)

- Event Planning (3)

- Fashion (42)

- Finance (8)

- Gifts / Misc (6)

- Home Decor (44)

- Jewelry (39)

- Pets (3)

- Philanthropy (1)

- Real Estate (12)

- Services (21)

- Sports / Golf (14)

- Vacation / Travel (60)

- Watches / Pens (14)

- Wines / Vines (24)

- Yachting / Boating (15)

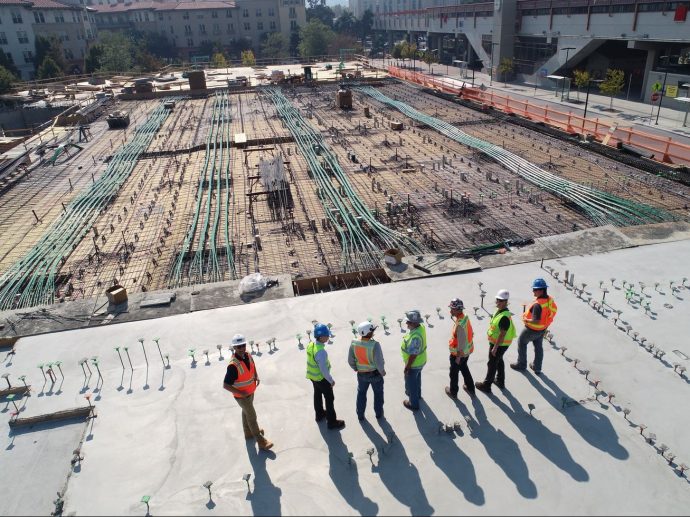

Steps to Planning Your Manufacturing Plants Construction

Published

10/13/2021The process of building a new manufacturing plant or expanding an existing one may be both thrilling and frustrating. There are many obstacles that can develop along the route, so being as prepared as possible is a smart idea. Consider these tips when planning your plant’s construction.

Acquire Land

If you're constructing a new manufacturing facility, the first consideration should be location and the type of land acquisition required. You'll need to make sure you have enough space for your purposes, such as loading docks, staff parking, and any other requirements specific to the type of facility you're building. At this phase, you should also make an assessment of potential barriers, such as wetlands, infrastructure, and potential economic incentives. Ensure that the land is well lit both during the day and at night for the safety of the employees you will bring on board. Install solar floodlights to ensure that lighting is sufficient for the task ahead.

Get the Relevant Permits and Approvals

The next stage is to figure out what permits and approvals you'll need to start building. This can be a challenging stage, so if you haven't done so already, now is the time to call in your building contractor. Depending on your situation, you may require numerous layers of clearances before building can begin, which might be frightening. Most projects require municipal zoning rules, protective covenants, stormwater management, site plan approval, state plan approval, and local permission. This can take a long time if you don't grasp how the procedure works.

Get Your Finances Right

It's time to consider finance once you've decided where you'll build your business and have the necessary permissions. There are a variety of financing sources available, including grants and loans. For each manufacturer, not every option will be the best one. An expert contractor can assist you in determining which financing choices are best suited to your specific requirements. The construction is likely to cost quite much, but an expert contractor can help you create a budget and predict the cost.

Create a Concept and a Design

One of the most crucial phases is design and concept, and it's also the most fun to get to. You and your contractor will begin to envision what your manufacturing facility or addition will look like in this step, and you will begin the creative process. This may take some time, and the final product may not be precisely what you had in mind. Be adaptable and consult specialists to help you develop a manufacturing facility that satisfies all of your requirements and incorporates the features you desire.

Decide Who Will Carry out the Project

Following the completion of your design and concept, the following stage is to choose a delivery mechanism. Will a general contractor and/or a construction manager be required? This is the time to consider who you'll need in place and what kind of expertise they'll need to get started.

Create a Schedule

The construction timetable is an important aspect of your new building. It can have an impact on financing terms, relocation efforts, output estimates, and a variety of other factors that aren't directly related to the new plant's physical construction. There are numerous factors that can influence the scheduling. Some factors are beyond your control (such as the weather), but the majority are. For the most part, more advanced planning on your part will assist keep the project on track.

Purchase The Relevant Equipment

You may need to purchase specific equipment depending on the type of manufacturing plant you're developing or expanding. For instance if you are a packaging plant, you will need an automatic can sealer machine. This and other food processing plants, for example, have different equipment requirements than other types of plants. Remember to factor this into your overall pro forma analysis. Plan ahead of time for construction equipment such as overhead cranes and sophisticated lifting equipment.

Plan for Future Expansion

Although it may appear to be a long way off, planning for future development might assist you in building now. Your manufacturing plant becomes scalable if it is built in such a way that it will be easy to expand in the future. Make sure there is enough space for expansion and layout operations so that there is minimal interruption.

Plan How Your Building Will Be Constructed

There are a few more things to think about before you start digging. What method will you use to develop your structure? Is it going to be made of concrete or metal? What kind of lighting is going to be used? Do you wish to make your building as eco-friendly as possible? Consider total occupancy, floor loads, clear span, ceiling heights, power requirements, HVAC requirements, and other requirements that your manufacturing plant will require to become fully operational. To save time and ensure efficiency during construction, ensure that the site has a portable bathroom which is environmentally friendly, durable and customizable to your project needs.

Hire the Right Guide

Even though the process of constructing or building a manufacturing plant might be frightening, partnering with a reliable Construction Project Consultant can make it go as smoothly as possible. When you're not sure what to do next, a contractor who has built the type of facility you require can best advise you. Your partner will work with you from concept to completion to ensure that everything goes according to plan, and will have no trouble communicating with you and your team.

Conclusion

You'll be well on your way to a successful project that meets your objectives, stays within your budget, and is completed on time if you understand the process and choose the proper industrial contractor to be your building partner.