Categories more

- Adventures (16)

- Arts / Collectables (15)

- Automotive (37)

- Aviation (11)

- Bath, Body, & Health (76)

- Children (6)

- Cigars / Spirits (32)

- Cuisine (16)

- Design/Architecture (21)

- Electronics (12)

- Entertainment (4)

- Event Planning (5)

- Fashion (44)

- Finance (9)

- Gifts / Misc (6)

- Home Decor (44)

- Jewelry (40)

- Pets (3)

- Philanthropy (1)

- Real Estate (14)

- Services (22)

- Sports / Golf (14)

- Vacation / Travel (60)

- Watches / Pens (14)

- Wines / Vines (24)

- Yachting / Boating (16)

What Makes Belt Conveyors Essential For Industrial Workflows?

Published

09/09/2025There are the unsung heroes in every industry — those tools and systems that ensure everything runs smoothly without much attention. Belt conveyors are one of those silent heroes.

They may appear to be mere moving belts at first glance. However, they are the lifeline of innumerable workflows, where materials, goods, and resources move in a smooth manner.

Consider them the intermediaries between processes, raw material handling, production, packaging, storage, and delivery. In their absence, operations would grind to a halt, the efficiency would decline, and the costs would skyrocket.

In other words, they introduce uniformity, dependability, and versatility to the contemporary workflow, whether it be a high-speed warehouse or a factory moving heavy weights.

So, they are not just valuable in terms of transportation but also in terms of enhancing productivity, safety, and sustainability in industries. Let us further explore the reasons for its importance for proper industrial operations.

1. Flexible Movement in a Variety of Conditions

The main distinction of belt conveyors lies in their capacity to work with a variety of products, both fragile consumer items and heavy industrial products. Their design features a continuous loop, powered by pulleys and motors, which facilitates smooth, controlled movement along straight paths, inclines, declines, and even curves.

This flexibility enables them to be adapted to special facility layouts and industry-specific requirements. They are also resilient in terms of being able to move textiles along production lines, coal in mining, and luggage in airport baggage systems, among others.

This way, their flexibility renders them essential to the industries that depend on diverse and dynamic processes.

2. Optimizing Material Handling

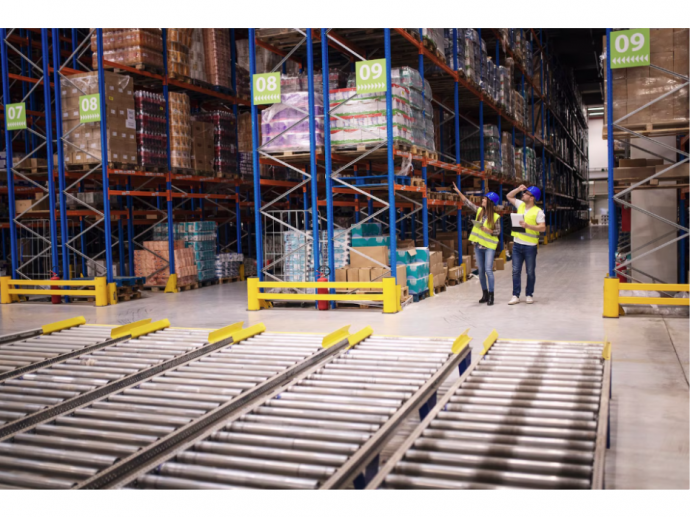

Industrial operations revolve around efficiency, and belt conveyors are instrumental in this. They achieve high speed and accuracy by automating the transport of materials, which is often difficult to handle manually.

It minimizes the possibility of human error, delays, and dependence on labor-intensive processes. Ultimately, the outcome is accelerated order fulfillment, reduced production line congestion, and improved throughput.

In addition to enhancing efficiency, conveyors contribute to workplace safety by minimizing injuries associated with manual lifting and transportation. These advantages in the long run accumulate to make belt conveyors a very economical investment, with increased productivity, reduced interruptions, and significant savings.

3. Scalable Automation to Maximize Industrial Productivity

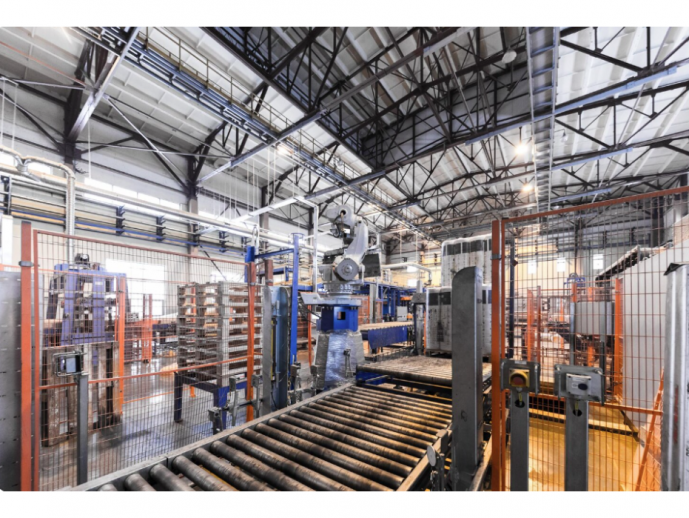

The invention of belt conveyors revolutionized productivity in industries through automation. Their influence today is evident in various industries, including automotive, manufacturing, mining, and logistics.

Their scalable nature allows them to accommodate any size of operation, whether a small workshop or a large distribution hub. They also facilitate just-in-time manufacturing and help maintain production schedules by enabling a constant flow of work.

Moreover, these machines can be easily integrated with automated processes, such as robotics and sorting equipment. It further increases productivity. This scaling and ability to adapt to business requirements make belt conveyors a pillar of industrial automation and efficiency.

4. Improving Safety and Worker Ergonomics

Not only do belt conveyors increase productivity, but they also spare workers the burden of manual handling. In this context, they minimize the number of repetitive lifts, bends, and transfers, which reduces the risk of musculoskeletal injuries and workplace accidents.

Most conveyors also have an integrated level of safety, which includes trip cords, emergency stop features, and obstacle detection sensors. As a result, potential hazards can be dealt with as soon as they arise.

This proactive safety management enables a safer working environment and minimizes the downtime that may be due to accidents. Businesses, in turn, get a more motivated workforce, fewer compensation claims, and improved workplace sustainability in the long term.

5. Sustainability through Efficient, Durable Design

Industries are becoming more concerned with sustainability. For this reason, current belt conveyors have been designed to meet such objectives. Constructed using energy-efficient motors, low-friction belts and tough materials, they reduce energy usage and increase the range of operation.

The result?

The waste is minimized, leading to a reduced environmental impact. There are also sophisticated systems that incorporate regenerative braking, which recaptures energy during operational tasks to reuse it.

These characteristics not only minimize carbon footprints but also enable companies to reduce their operational costs without significantly lowering the level of performance. Belt conveyors are, hence, a sustainable and cost-effective option, which promotes industrial development and supports the greener supply chains.

6. Connectivity with Smart Systems for Visibility

Modern belt conveyors are not just a mechanical method of transportation but a combination of digital technologies. It is to provide complete awareness of the operations.

They come with IoT sensors, weight scales, and tracking devices that generate real-time information about load conditions and performance indicators. This data is incorporated into warehouse management and ERP systems.

In turn, you get predictive maintenance, precise inventory tracking, and simplified workflows. Also, it enables managers to gain actionable visibility into bottlenecks, inefficiencies, and performance trends, enabling them to streamline processes in real-time.

Thus, through the combination of physical movement and smart monitoring, conveyors provide agility and responsiveness. It allows businesses to be efficient and fulfill customer expectations as they expand.

Conclusion

In every corner of industry, from factories to distribution hubs, belt conveyors quietly shape the rhythm of operations. They do more than move goods; they create consistency, speed, and reliability in workflows that would otherwise face bottlenecks and inefficiencies.

Their role also extends to protecting workers, cutting costs, and supporting sustainability initiatives—all while adapting to the evolving demands of modern supply chains. So, as industries continue to embrace automation and smart technologies, conveyors remain the backbone that ensures growth and resilience.

After all, they are not just machinery but enablers of progress, driving industries toward a more efficient and sustainable future.